Welcome to Nanotechnology

The ARTEPEÇAS manufactures homogenizers with flow from 10 to 30.000 liters/hour and pressure up to 2.000 bar. Produces equipment for all segments.

Our homogenizer is produced with the highest technology to attend the specific need of each product..

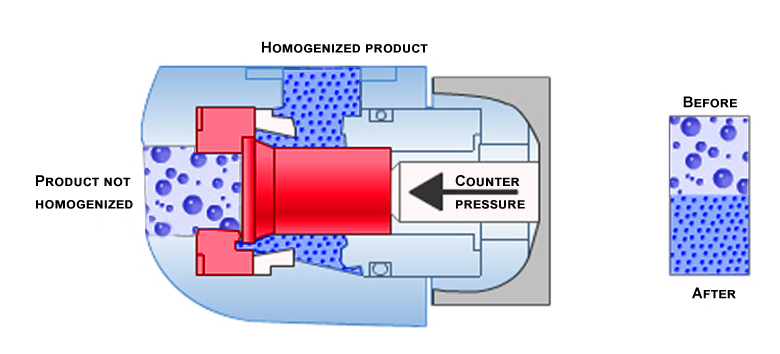

Homogenization

The homogenizer is triggered by an electric engine which is responsible for moving the gearbox through the crankshaft shaft (activation), which is driven by pulleys and belts; It is responsible for moving the pistons inside the valve block.

The crankshaft shaft moves the pistons causing the product to enter the valve block through the suction valves and exit through a smaller opening, through the discharge valves, at a very high speed and pressure. Then the product goes to the homogenization block, entering the seat, which as an even smaller orifice, which results in an increase in speed and pressure, causing it to collide with the homogenization valve, which is responsible for the shearing of the particles, ending the process and returning the initial pressure.

The pressure of the product is controlled through the manometer. The pressure must be regulated according to the characteristics of each product, and can vary from 10 to 2000 BAR.

It is a fully mechanical process that occurs through speed, pressure and impact, not altering the original characteristics of the product.

The purpose of the homogenization is to decrease the particles diameter of any liquid or viscous product, creating stability, in other words, preventing phase separation.

Applications

Homogenizers find applications in an infinity of processes where the reduction of the particles to the size of microns, sub-microns and nanos becomes essential for product quality, uniformity and standard. In the food, beverage and juice industry, homogenization is widely used because the homogenous texture is much more attractive to consumers.

Homogenization can also be applied in the pharmaceutical industry, being used for the disruption of cells, for the creation of new medicines and vaccines.

In the cosmetic industry can be used to reduce particles to a such small size, nanoparticles, less than a micron, which can be absorbed by the skin.

Some Customers

Come to be part of our customer gallery.